See what you can learn about birds by studying the pellets they leave behind.

Most birds cannot chew their food, and owls are no exception. Owls usually swallow their prey whole. Owls differ from other species of birds because they do not have a crop, the baglike organ used to store food after it has been swallowed so that it can be digested later. In owls, food passes directly from the mouth to the gizzard. The gizzard is an organ that uses digestive fluids and bits of sand and gravel to grind and dissolve usable tissue from the prey.

The types of tissue that can be dissolved by an owl’s digestive system include muscle, fat, skin, and internal organs. These tissues are broken down into a variety of nutritional substances by the owl’s gizzard and intestines. Some of these tissues (e.g., fur and bones) cannot be digested. The digestible material, along with other waste collected throughout the body, is ejected from the vent, which is the combination reproductive and excretory opening in birds. The pasty white excrement is known as urea. It is rich in nitrogen and similar to urine in mammals, only thicker.

What happens to the indigestible material?

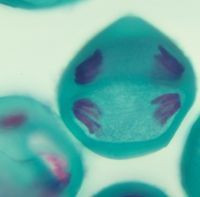

Indigestible material left in the gizzard such as teeth, skulls, claws, and feathers are too dangerous to pass through the rest of the owl’s digestive tract. To safely excrete this material, the owl’s gizzard compacts it into a tight pellet that the owl regurgitates. The regurgitated pellets are known as owl pellets.

Owl pellets are useful to researchers because they can find out quite a bit about an owl’s lifestyle through careful examination of the pellet’s contents. Since most of the prey’s bones are not actually broken during the attack and the subsequent digestion process, they can be readily identified in the pellet. Most pellets include a skull or skulls, which makes identification of the prey relatively simple. If an owl consumes multiple prey in a short period of time, it forms one large pellet from the remains.

Large owls are obviously capable of making large pellets. However, since large owls do not always eat large prey, one cannot always determine the size of the owl that left a given pellet solely based on the size of the pellet. In addition, a startled owl may eject a pellet that is not fully compacted, thereby giving the pellet a larger appearance than normal. Other species of birds such as hawks and eagles produce pellets, but they are smaller and contain fewer animal parts than those produced by owls.

Storing and regurgitating pellets

An owl pellet generally reaches its final form a few hours after the owl has eaten. However, the pellet is not usually ejected immediately after it is formed. Owls can store a pellet in a structure known as the proventriculus for as long as 20 hours before disgorging it. Since the stored pellet partially blocks the entrance to the digestive system, it must be ejected before the owl can eat again. Young owls do not produce pellets until they have begun to eat their prey whole.

The actual process of regurgitating a pellet lasts from a few seconds to several minutes. The pellet is forced out by spasms of the owl’s esophagus. These spasms make the owl look like it is coughing painfully. However, it is not hurt by the process because the pellet remains soft and moist until it leaves the owl’s body.

Identifying pellets

The shape and texture of a given owl pellet depends on the species of the owl that produced it and the type of prey that the owl consumed. Some pellets are tightly compacted, oval, and furry. Others are loosely compacted with an irregular shape. Pellets are moist when they are first ejected, but quickly dry out and start to decompose once they leave the owl’s body. Owl pellets are typically found near places where owls perch, such as under trees and near barns.

Barn Owl pellets are typically medium sized, smooth, cylindrical, and dark. The tiny Elf Owl has a very small pellet that is dry and loosely compacted, a result of its largely insect diet. The Great Horned Owl can produce pellets that are 3 to 4 inches long. These pellets are usually cylindrical and tightly compacted. The exterior of the pellet can vary greatly due to the vast array of prey that Great Horned Owls consume.

Owl pellet dissection resources

An owl pellet dissection gives students a glimpse into the life of an animal they may never see in the wild. Pellets tell us what the owl eats, where it is likely to roost, what small mammals live nearby, and even the relative proportions of those animals. Safe owl pellet dissections can build toward several NGSS standards across grade levels.